Style R which is energised when the assembly is pressurised. The RX is designed to fit the same groove design as a standard Style R, making the joints interchangeable, however consideration should be given to the difference in finished make up distance. The geometry of this modified design induces a pressure energising effect when the assembly is pressurised, improving the efficiency of the seal.

Style RX

STYLE RX

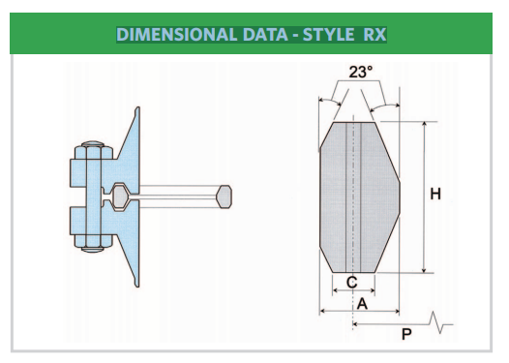

The Style RX is an adaptation of the standard Style R which is energised when the assembly is pressurised. The RX is designed to fit the same groove design as a standard Style R, making the joints interchangeable, however consideration should be given to the difference in finished make up distance.The geometry of this modified design induces a pressure energising effect when the assembly is pressurised, improving the efficiency of the seal. Designs are also available for subsea applications on existing assets, however, current API 17D does not support use of SRX Ring Type Joints.

STYLE RX TOLERANCES

Surface finish of the Style RX Ring Type Joint sealing faces (23° angled faces) shall not be greater than 1.6 µm Ra / 63 µin RMS.

NOTE 1

The pressure passage hole illustrated in the Ring Type Joint cross section ensures equalization of pressure equalization of pressure that may be generated in the grooves when the flange assembly is closed. These pressure passage holes are mandatory in the ring sizes RX82-91 inclusive. Centre line of hole shall be located at mid point of dimension “C’’ (width of flat).

Hole diameter shall be as follows:

- 1.5mm ±0.5 for rings RX82 through RX85;

- 2.3mm ±0.5 (2.4mm ±0.5 for API 6A) for rings RX86 and RX87;

- 3.0mm ±0.5 for rings RX88 through RX91.

DIMENSIONAL DATA

RING TYPE JOINTS

ASME B16.20 and API 6A

Style RX

DIMENSIONAL DATA

*Pressure Class Ratings API 6A (psi) & Nominal Pipe Sizes (inches)

General Notes

Dimensions in mm. Figures stated are for information only. Please refer to the current version of the original standards for dimensional information.

Tolerances

OD = outside diameter of ring, + 0.51, 0.00. A = width of ring, + 0.20, – 0.00 – Variation in width throughout the entire circumference of any ring shall not exceed 0.10 within these tolerances.

C = width of flat, + 0.15, – 0.00. D = height of outside bevel, + 0.00, – 0.76. H = height of ring, + 0.20, – 0.00 – Variation in height throughout the entire circumference of any ring shall not exceed 0.10 within these tolerances. R1 = radius of ring, +/- 0.5. 23 deg = angle, +/- 0 deg 30 min. E = hole size. +/- 0.5

NOTES

- Rings RX-82 through RX-91 only require one pressure passage hole as illustrated. The centreline of the hole shall be located at the midpoint of dimension C.

- Tolerance on these dimensions is + 0.00, – 0.38.