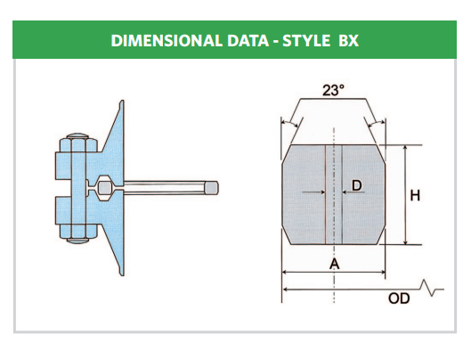

The Style BX energized Ring Type Joints, manufactured in accordance with ASME B16.20, API 6A and API 17D, are designed for use on API 6BX flanges on pressure systems rated up to 20,000 psi. When correctly fitted, the style BX gasket allows virtual face to face contact of the flange faces which means that the gasket is fully confined on both the inner and outer diameters. All BX gaskets incorporate a pressure balance hole to ensure equalization of pressure which may be generated in the grooves

Style BX

NOTE 1

Machined radii located between all 23° angled sealing facings and the top and bottom flat faces, shall be 8% to 12% of the ring height ‘H’

STYLE BX TOLERANCES

Surface finish of the Style BX Ring Type Joint sealing faces (23° angled faces) shall not be greater than 0.8 µm Ra / 32 µin RMS

DIMENSIONAL DATA

*Pressure Class Ratings API 6A (psi) & Nominal Pipe Sizes (inches)

GENERAL NOTES

a) Dimensions in mm.

b) Figures stated are for information only. Please refer to the current version of the original standards for dimensional information.

c) Radius R, shall be 8% to 12% of the gasket height, H.

d) Nominal sizes shown in parenthesis are as listed in ASME B16.20.

Tolerances

OD = outside diameter of ring, + 0.00, – 0.15

H = height of ring, + 0.20, – 0.00 – Variation in height throughout the entire circumference of any ring shall not exceed 0.10 within these tolerances.

A = width of ring, + 0.20, – 0.00 – Variation in width throughout the entire circumference of any ring shall not exceed 0.10 within these tolerances.

ODT = outside diameter of flat, +/- 0.05

C = width of flat, + 0.15, – 0.00

D = hole size, +/-0.5

R = radius of ring [see general note (c)]

23 deg = angle, +/- 0 deg 15 min

NOTE

1. One pressure passage hole is required per gasket as illustrated. The centreline of the hole shall be located at the midpoint of dimension C.