RUBBER COATED RING TYPE JOINTS.

BLIND AND ORIFICE RING TYPE JOINTS.

RUBBER COATED RING TYPE JOINTS

This is an oval Ring Type Joint totally enclosed in a nitrile rubber coating. The Ring Type Joint material is usually soft iron or low carbon steel.

This type of gasket has three main functions:

- It is used in pressure testing to minimize damage to flanges.

- The rubber contact points provide additional seals while protecting the flange surfaces.

- It provides increased assurance against corrosion, which can occur between conventional Ring Type Joints and the engaged surfaces of the groove. A wide range of standard sizes are available, with special sizes available upon request.

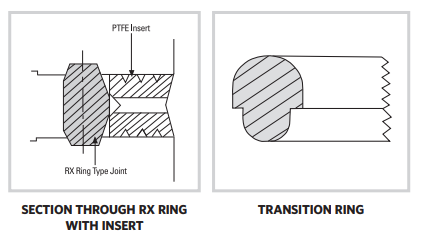

STYLE R AND RX WITH PTFE INSERTS

Style R and RX Ring Type Joints can also be supplied with PTFE inserts, in order to reduce turbulent flow and eliminate gasket/flange erosion. For the RX style Ring Type Joints, the insert is specially designed with radially drilled pressure passage holes so that the self energizing performance of the RX Ring Joint is not impaired. As can be seen in the sectional view, the insert is located between the inside diameter of the Ring Type Joint and the bore of the flange. On assembly, the insert is completely trapped between the make up of the flanges, filling the annular space between the flange bore and gasket.