All Ring Type Joints are manufactured in accordance with the industry standards API 6A, ASME B16.20 or to specific customer requirements. These Ring Type Joints are produced from fully traceable materials and are supplied to NACE specifications upon request. Ring Type Joints manufactured to ASME B16.20 are permanently marked according to standard. Each Ring Type Joint manufactured to an API standard is identified by low stress stamping with style, ring number, API license number, material reference, Product Specification Level 4 (PSL-4), a unique Flexitallic material identification number, and month and year of manufacture. Such full and comprehensive traceability, from material source with mill certification to final supply, is an essential ingredient of the company’s strict quality assurance procedures and exceed those demanded by the highest API 6A approvals

Ring Type Joints

The metallic ring type joint is used in the petroleum industry, where high pressure applications Necessitate the need for a high integrity seal

Materials

The gasket material should be selected to suit the service conditions. It is always recommended that the gasket material be softer than the mating flanges. The more popular Ring Type Joint materials, with the stated maximum hardness and identification as specified in API 6A and ASME B16.20, are shown in the table below. For more highly specialised applications, Ring Type Joints can be machined from Duplex steels and other exotic materials such as Inconel®, Incoloy® , and Hastelloy®. The Technical Department is available to advise on other materials

Protective Coating

In accordance with API Specifications, soft iron and low carbon steel Ring Type Joints are protected with electroplated zinc to a maximum thickness of 8pm. Alternative material coatings can be supplied on request.

Product Dimensions

NOTES

(a) The maximum hadness values applied to Soft Iron may be required for Low Carbon Steel

(b) Material identification of RTJ’s manufactured in accordance with API-6A will incude ‘- 4’ immediately after the material identification. Eg. S316-4.

(c) The maximum hardness values listed are specified by the following bodies: A = API, B = ASME

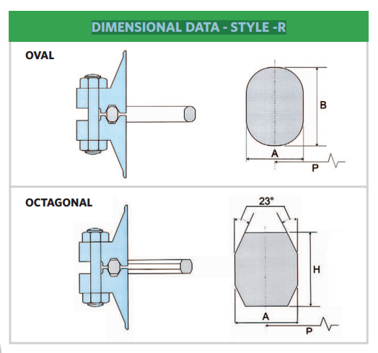

Style R

The Ring Type Joint was initially developed for high pressure/temperature applications found in the petroleum industry and is primarily used in the oil field on drilling and completion equipment. However, today this product range can also be found on valves and pipework assemblies, along

with some high integrity pressure vessel joints.

STANDARD STYLE R RING TYPE JOINTS

These are are manufactured in accordance with ASME B16.20 or API 6A. Available in both oval and octagonal configurations, both types are interchangeable on the modern octagonal type grooved flanges.As with all solid metal Ring Type Joints including Style R, it is recommended to replace the ring when flanged connection is broken.

STYLE R TOLERANCES

Surface finish of the Style R Ring Type Joint sealing faces (radiused ends of an Oval and the 23° angled faces of an Octagonal shape) shall not be greater than 1.6 µm Ra / 63 µin RMS. Flexitallic Style R Ring Type Joints can be manufactured in accordance with all relevant

standards to suit the following flange designations:

- API 6A

- ASME B16.5

- ASME B16.47 SERIES A

- BS1560